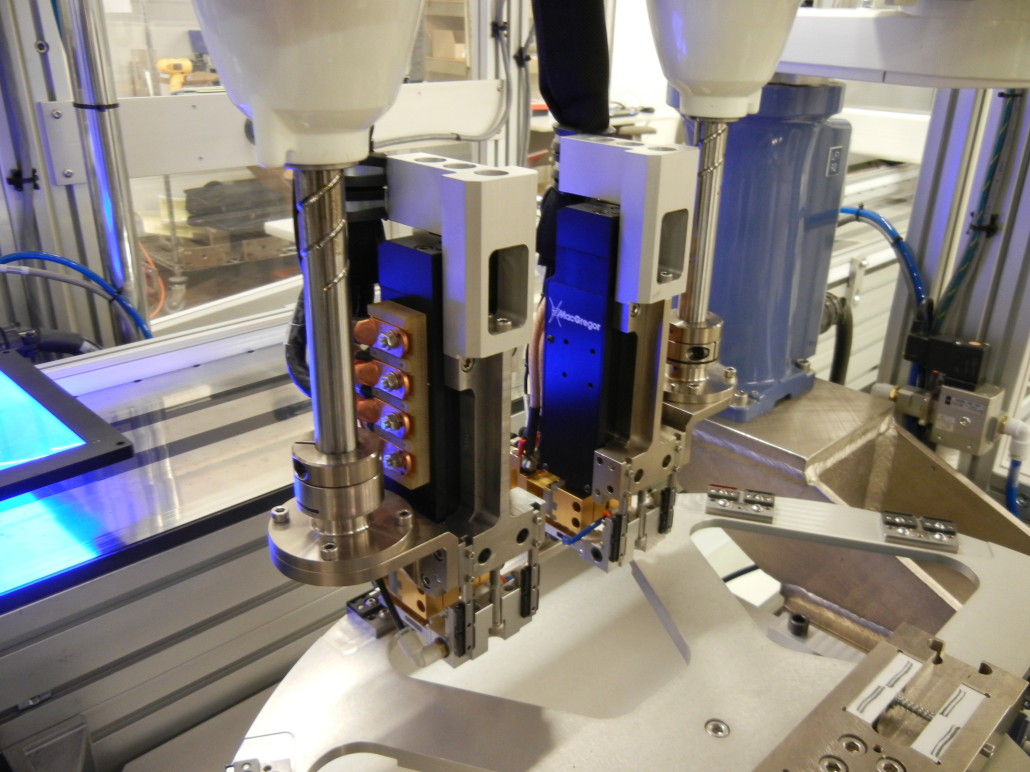

High precision automated systems are computer-controlled systems that are designed to perform tasks with a high degree of accuracy and precision. These systems are used in a wide variety of industries, including manufacturing, healthcare, and scientific research. They can be used to perform tasks such as assembling products, dispensing medication, and conducting experiments.

High precision automated systems offer a number of advantages over manual systems. They are more accurate and precise, which can lead to improved product quality and reduced costs. They are also faster than manual systems, which can lead to increased productivity. In addition, high precision automated systems are often more reliable than manual systems, which can help to reduce downtime and maintenance costs.

The development of high precision automated systems has been driven by advances in computer technology. These advances have made it possible to create systems that are capable of performing tasks with a high degree of accuracy and precision. In addition, the development of new sensors and actuators has made it possible to create systems that can operate in a variety of environments.

Read also:Discover The Legendary Chicago House Of Blues

High Precision Automated Systems

High precision automated systems are computer-controlled systems that are designed to perform tasks with a high degree of accuracy and precision. These systems are used in a wide variety of industries, including manufacturing, healthcare, and scientific research. They can be used to perform tasks such as assembling products, dispensing medication, and conducting experiments.

- Accuracy

- Precision

- Speed

- Reliability

- Efficiency

- Repeatability

- Versatility

These key aspects are essential for high precision automated systems to be able to perform their tasks effectively. Accuracy and precision are important for ensuring that the system can produce consistent results. Speed and reliability are important for ensuring that the system can meet production demands. Efficiency and repeatability are important for ensuring that the system can operate with minimal downtime. Versatility is important for ensuring that the system can be used for a variety of tasks.

High precision automated systems are playing an increasingly important role in a wide variety of industries. As these systems continue to develop, they are likely to become even more essential for businesses that want to improve their productivity and quality.

1. Accuracy

Accuracy is the ability of a measurement or system to conform to a standard or true value. In the context of high precision automated systems, accuracy is essential for ensuring that the system can produce consistent and reliable results. This is especially important in industries such as manufacturing, where even small errors can lead to costly mistakes.

There are a number of factors that can affect the accuracy of a high precision automated system. These include the quality of the sensors and actuators used in the system, the design of the control system, and the operating environment. It is important to carefully consider all of these factors when designing and implementing a high precision automated system.

One of the most important ways to improve the accuracy of a high precision automated system is to use high-quality sensors and actuators. Sensors are used to measure the state of the system, while actuators are used to control the system's movement. The quality of these components will have a direct impact on the accuracy of the system.

Read also:Discover The Professional Behind The Wheel Introducing Tvc Pro Driver

The design of the control system is also important for ensuring accuracy. The control system is responsible for interpreting the data from the sensors and sending commands to the actuators. A well-designed control system will be able to quickly and accurately respond to changes in the system's environment.

Finally, the operating environment can also affect the accuracy of a high precision automated system. Factors such as temperature, humidity, and vibration can all affect the performance of the system's components. It is important to take these factors into account when designing and implementing a high precision automated system.

Accuracy is essential for high precision automated systems to be able to perform their tasks effectively. By carefully considering the factors that affect accuracy, it is possible to design and implement systems that can produce consistent and reliable results.

2. Precision

Precision is the degree to which a measurement or system conforms to a standard or true value. In the context of high precision automated systems, precision is essential for ensuring that the system can produce consistent and reliable results. This is especially important in industries such as manufacturing, where even small errors can lead to costly mistakes.

There are a number of factors that can affect the precision of a high precision automated system. These include the quality of the sensors and actuators used in the system, the design of the control system, and the operating environment. It is important to carefully consider all of these factors when designing and implementing a high precision automated system.

One of the most important ways to improve the precision of a high precision automated system is to use high-quality sensors and actuators. Sensors are used to measure the state of the system, while actuators are used to control the system's movement. The quality of these components will have a direct impact on the precision of the system.

The design of the control system is also important for ensuring precision. The control system is responsible for interpreting the data from the sensors and sending commands to the actuators. A well-designed control system will be able to quickly and accurately respond to changes in the system's environment.

Finally, the operating environment can also affect the precision of a high precision automated system. Factors such as temperature, humidity, and vibration can all affect the performance of the system's components. It is important to take these factors into account when designing and implementing a high precision automated system.

Precision is essential for high precision automated systems to be able to perform their tasks effectively. By carefully considering the factors that affect precision, it is possible to design and implement systems that can produce consistent and reliable results.

3. Speed

Speed is a critical factor in high precision automated systems. The ability of these systems to perform tasks quickly and efficiently is essential for their successful operation. There are a number of factors that can affect the speed of a high precision automated system, including the design of the system, the type of tasks being performed, and the operating environment.

- Design of the system

The design of the system can have a significant impact on its speed. Factors such as the type of sensors and actuators used, the control algorithms employed, and the overall architecture of the system can all affect its speed.

- Type of tasks being performed

The type of tasks being performed by the system can also affect its speed. Some tasks, such as simple assembly tasks, can be performed quickly and efficiently. Other tasks, such as complex scientific experiments, may require more time to complete.

- Operating environment

The operating environment can also affect the speed of a high precision automated system. Factors such as temperature, humidity, and vibration can all affect the performance of the system's components.

Speed is an essential factor for high precision automated systems. By carefully considering the factors that affect speed, it is possible to design and implement systems that can meet the demands of even the most challenging applications.

4. Reliability

Reliability is a critical aspect of high precision automated systems. These systems are often used in mission-critical applications, where even a small failure can have catastrophic consequences. As a result, it is essential that these systems are designed and built to be as reliable as possible.

There are a number of factors that can affect the reliability of a high precision automated system. These include:

- The quality of the components used in the system

- The design of the system

- The operating environment

It is important to carefully consider all of these factors when designing and building a high precision automated system. By using high-quality components, employing a robust design, and taking into account the operating environment, it is possible to create systems that are highly reliable.

One of the most important aspects of reliability is redundancy. Redundancy is the use of multiple components to perform the same function. This ensures that if one component fails, the system can continue to operate. Redundancy can be implemented at various levels, from the individual component level to the system level.

Another important aspect of reliability is maintenance. Regular maintenance can help to prevent failures from occurring. Maintenance should be performed according to the manufacturer's recommendations. It is also important to keep a record of all maintenance performed on the system.

High precision automated systems are essential for a wide variety of applications. By understanding the importance of reliability and taking steps to ensure that systems are reliable, it is possible to avoid costly downtime and ensure that these systems can be used to their full potential.

5. Efficiency

Efficiency is a crucial aspect of high precision automated systems. These systems are designed to perform tasks with a high degree of accuracy and precision, while also being efficient in their use of resources. This efficiency is essential for ensuring that these systems can be used in a cost-effective manner.

- Resource Optimization

High precision automated systems are designed to optimize the use of resources, such as energy, materials, and time. This is achieved through the use of efficient algorithms and control systems. For example, a high precision automated assembly system may be designed to minimize the amount of energy used by the robots and other equipment. This can lead to significant cost savings over time.

- Waste Reduction

High precision automated systems can also help to reduce waste. This is achieved by minimizing the amount of materials used in the production process. For example, a high precision automated cutting system may be designed to minimize the amount of scrap material produced. This can lead to significant cost savings and environmental benefits.

- Time Savings

High precision automated systems can also save time. This is achieved by automating tasks that would otherwise be performed manually. For example, a high precision automated welding system may be designed to weld parts together more quickly and accurately than a human welder. This can lead to significant time savings and increased productivity.

- Improved Quality

High precision automated systems can also improve the quality of products. This is achieved by eliminating human error from the production process. For example, a high precision automated assembly system may be designed to assemble products with a higher degree of accuracy and precision than a human assembler. This can lead to improved product quality and reduced warranty claims.

Overall, efficiency is a critical aspect of high precision automated systems. These systems are designed to be efficient in their use of resources, reduce waste, save time, and improve quality. By carefully considering the efficiency of these systems, it is possible to design and implement systems that can meet the demands of even the most challenging applications.

6. Repeatability

Repeatability is a critical aspect of high precision automated systems, ensuring that the system can produce consistent and reliable results even under varying conditions. It is the ability of a system to perform a task or process and achieve the same outcome repeatedly, with minimal variation. In the context of high precision automated systems, repeatability is essential for maintaining accuracy and precision over long periods of operation, reducing the likelihood of errors and defects.

- Consistent Performance

Repeatability ensures that the system performs consistently, regardless of factors such as changes in temperature, humidity, or operator skill. This is achieved through the use of precise control algorithms, high-quality components, and robust system design.

- Reduced Variability

High precision automated systems with good repeatability exhibit minimal variability in their outputs. This means that the system can produce products or perform tasks with a high degree of uniformity, reducing the likelihood of defects or inconsistencies.

- Predictable Outcomes

Repeatability allows manufacturers and engineers to predict the outcomes of automated processes more accurately. With consistent performance and reduced variability, businesses can optimize their production processes, reduce downtime, and improve overall efficiency.

- Quality Control

In industries such as manufacturing and healthcare, repeatability is crucial for maintaining product quality and ensuring regulatory compliance. Automated systems with high repeatability can consistently meet or exceed quality standards, reducing the risk of product recalls or safety issues.

Overall, repeatability is a fundamental characteristic of high precision automated systems, enabling them to deliver consistent, reliable, and predictable performance. It is a key factor in ensuring the accuracy, precision, and quality of automated processes, contributing to increased efficiency, reduced costs, and improved customer satisfaction.

7. Versatility

In the realm of industrial automation, versatility stands as a cornerstone of high precision automated systems. It empowers these systems with the adaptability and flexibility to perform a wide range of tasks with exceptional accuracy and precision. This versatility stems from advanced hardware designs, sophisticated software algorithms, and user-friendly interfaces that enable seamless integration into diverse production environments.

The practical significance of versatility in high precision automated systems is profound. It allows manufacturers to streamline their production processes, reduce downtime, and enhance overall efficiency. By eliminating the need for dedicated systems for each specific task, versatile automated systems offer a cost-effective and agile solution.

For instance, in the automotive industry, high precision automated systems are employed for various tasks, including welding, assembly, and inspection. The versatility of these systems enables them to adapt to different vehicle models and production requirements, ensuring a smooth and efficient manufacturing process. Similarly, in the electronics industry, versatile automated systems are used for intricate tasks such as component placement, soldering, and testing, contributing to the production of high-quality electronic devices with consistent precision.

In summary, the versatility of high precision automated systems is a key factor driving their adoption across a plethora of industries. It empowers these systems to tackle diverse tasks with accuracy, precision, and efficiency, thereby enhancing productivity, reducing costs, and enabling manufacturers to adapt to changing market demands.

FAQs on High Precision Automated Systems

This section addresses frequently asked questions about high precision automated systems (HPAS), providing concise and informative answers to common concerns and misconceptions.

Question 1: What are the key benefits of HPAS?

Answer: HPAS offer numerous advantages, including enhanced accuracy and precision, increased speed and efficiency, improved reliability, reduced waste, and optimized resource utilization.

Question 2: How do HPAS improve accuracy and precision?

Answer: HPAS employ advanced sensors, actuators, and control algorithms to minimize errors and variations, ensuring consistent and precise performance.

Question 3: Are HPAS suitable for various industries?

Answer: Yes, HPAS find applications in a wide range of industries, including manufacturing, healthcare, and scientific research, due to their versatility and adaptability.

Question 4: How do HPAS contribute to cost reduction?

Answer: By increasing efficiency, reducing waste, and minimizing downtime, HPAS can significantly lower production costs and improve overall profitability.

Question 5: What are the maintenance requirements for HPAS?

Answer: HPAS require regular maintenance to ensure optimal performance and longevity. Maintenance schedules and procedures vary depending on the specific system and manufacturer's recommendations.

Question 6: How do HPAS impact the workforce?

Answer: HPAS can augment human capabilities, freeing up workers from repetitive or hazardous tasks and enabling them to focus on higher-value activities that require human judgment and creativity.

In summary, HPAS offer a multitude of advantages, enhancing accuracy, precision, efficiency, and cost-effectiveness across diverse industries. Proper maintenance and integration with human expertise ensure optimal performance and a positive impact on the workforce.

Transitioning to the next article section: These FAQs provide valuable insights into the capabilities and benefits of high precision automated systems. For further exploration, the following sections delve into specific applications and case studies.

Tips on Utilizing High Precision Automated Systems

High precision automated systems offer a plethora of benefits for businesses looking to enhance their productivity and accuracy. Here are several tips to help you effectively utilize these systems:

Tip 1: Define Clear ObjectivesArticulate specific and measurable goals for your automated system. This will guide your design and implementation process, ensuring the system meets your unique requirements.Tip 2: Choose the Right System

Thoroughly research and evaluate different automated systems to select the one best suited for your application. Consider factors such as accuracy, speed, reliability, and cost.Tip 3: Implement Proper Training

Provide comprehensive training to operators and maintenance personnel to ensure they can effectively use and maintain the automated system. This will maximize its performance and lifespan.Tip 4: Integrate with Existing Infrastructure

Seamlessly integrate the automated system with your existing production and IT infrastructure. This will minimize disruption and ensure smooth operation within your overall workflow.Tip 5: Monitor and Maintain Regularly

Establish a regular maintenance schedule to monitor the system's performance, identify potential issues, and perform necessary maintenance. This proactive approach will prevent costly downtime and ensure optimal operation.Tip 6: Leverage Data Analytics

Utilize the data generated by the automated system to analyze trends, identify inefficiencies, and make data-driven decisions. This will help you continuously improve your processes and maximize the system's benefits.Tip 7: Seek Expert Support

Consider partnering with a reputable system integrator or automation expert to provide guidance and support throughout the implementation and operation of your automated system.Tip 8: Stay Updated with Advancements

Keep abreast of the latest advancements in high precision automated systems. Attend industry events, read technical publications, and consult with experts to ensure your system remains at the cutting edge of technology.By following these tips, you can effectively harness the power of high precision automated systems to drive innovation, improve quality, and achieve operational excellence within your organization.

In conclusion, high precision automated systems offer a transformative solution for businesses seeking to enhance their productivity, precision, and overall competitiveness. By carefully considering these tips, you can maximize the benefits of these systems and unlock their full potential.

Conclusion

High precision automated systems are revolutionizing various industries, offering unparalleled accuracy, precision, and efficiency. As these systems continue to advance, they will play an increasingly critical role in shaping the future of manufacturing, healthcare, and scientific research. By embracing the transformative power of high precision automated systems, businesses can unlock new levels of productivity, innovation, and competitiveness.

The journey towards fully autonomous and self-optimizing automated systems is ongoing, with continuous advancements in artificial intelligence, machine learning, and robotics. These technologies will further enhance the capabilities of high precision automated systems, enabling them to handle even more complex tasks and make real-time decisions. The future holds immense potential for these systems, promising to transform industries and redefine the boundaries of human ingenuity.