The linear actuator is a transformative piece of technology that has redefined a multitude of industries. Known for its ability to convert rotational motion into linear motion, it is a crucial component in applications ranging from industrial machinery to home automation. With an expanding array of uses, understanding the functionality and benefits of linear actuators can greatly enhance the efficiency and precision of various mechanical systems.

Linear actuators come in various forms, including electric, hydraulic, and pneumatic types, each tailored to specific tasks and environments. They are celebrated for their versatility, reliability, and efficiency, making them indispensable in sectors such as manufacturing, robotics, and automotive industries. As technology continues to evolve, linear actuators are becoming more advanced, offering increased performance and adaptability.

For those looking to incorporate linear actuators into their systems, it's important to consider factors such as load capacity, speed, and environmental conditions. This comprehensive guide will delve into the intricate details of linear actuators, providing insights into their workings, types, applications, and the future landscape of actuator technology. Whether you're an engineer, a hobbyist, or just curious about mechanical innovations, this article aims to equip you with the essential knowledge to harness the power of linear actuators effectively.

Read also:Ultimate Guide To The Legendary Sankat Mochan Hanuman Temple

Table of Contents

- What is a Linear Actuator?

- How Do Linear Actuators Work?

- Types of Linear Actuators

- Applications of Linear Actuators

- Benefits of Using Linear Actuators

- Choosing the Right Linear Actuator

- Linear Actuators in Industrial Machinery

- Linear Actuators in Home Automation

- Linear Actuators in Robotics

- Linear Actuators in the Automotive Industry

- Future of Linear Actuator Technology

- Maintenance and Care of Linear Actuators

- Common Problems and Solutions

- Frequently Asked Questions

- Conclusion

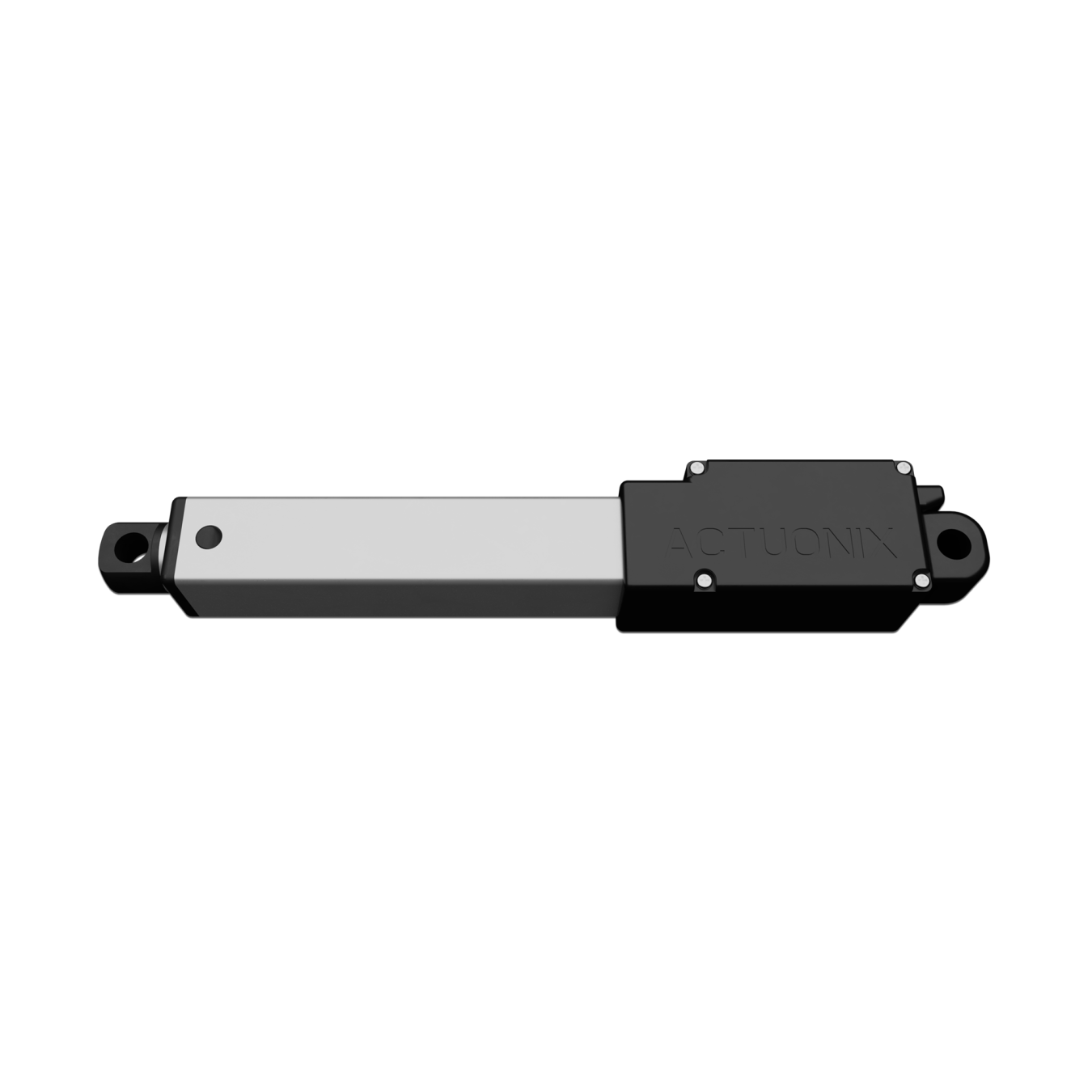

What is a Linear Actuator?

At its core, a linear actuator is a device that creates motion in a straight line, as opposed to the circular motion of a conventional electric motor. This motion is crucial in a variety of applications that require precise control and movement, such as opening and closing valves, lifting loads, or positioning objects. A linear actuator typically consists of a motor, a screw drive, and a sliding carriage, all working in harmony to produce linear motion.

How Do Linear Actuators Work?

Linear actuators operate based on the principle of converting energy into motion. The most common mechanism involves a motor driving a screw thread, which in turn moves a nut along its length, creating the linear motion. Depending on the type of energy used—be it electrical, hydraulic, or pneumatic—the mechanism may vary. Electric linear actuators, for instance, use an electric motor to drive the screw, while hydraulic actuators use fluid pressure.

Types of Linear Actuators

There are several types of linear actuators, each designed for specific applications:

- Electric Actuators: These are the most common type, using electricity to drive the motor that turns the screw.

- Hydraulic Actuators: These use pressurized fluid to create movement, ideal for heavy-duty applications.

- Pneumatic Actuators: These utilize compressed air to produce motion, often used in environments where electric actuators might pose a risk.

Applications of Linear Actuators

Linear actuators are used in a wide array of applications, thanks to their versatility and precision. Some of the common uses include:

- Industrial Automation: Used in manufacturing and assembly lines for tasks like moving parts, controlling machinery, or adjusting equipment.

- Automotive Industry: Essential in adjusting seats, windows, and other vehicle components.

- Robotics: Provides precise movement control, essential for robotic arms and automated systems.

Benefits of Using Linear Actuators

The advantages of linear actuators are numerous, making them a preferred choice in many industries:

- Precision: Linear actuators offer accurate control over movement and positioning.

- Efficiency: They are energy-efficient, often requiring less power to operate compared to other mechanisms.

- Adaptability: With various types available, they can be adapted to suit different needs and environments.

Choosing the Right Linear Actuator

When selecting a linear actuator, consider the following factors:

Read also:Access Your Stormont Vail Mychart Online Today

- Load Capacity: Ensure the actuator can handle the weight and force requirements of your application.

- Speed: Different actuators offer varying speeds, so choose one that matches your needs for quick or gradual movement.

- Environmental Conditions: Consider the operating environment, as some actuators are better suited to harsh conditions than others.

Linear Actuators in Industrial Machinery

In industrial settings, linear actuators play a pivotal role in enhancing automation and efficiency. They are used for tasks such as:

- Material Handling: Moving products along production lines or adjusting conveyor belts.

- Machine Tooling: Precise positioning of tools and components in CNC machines.

- Packaging: Adjusting packaging machines to accommodate different sizes and shapes.

Linear Actuators in Home Automation

Linear actuators have become integral to modern home automation, offering convenience and efficiency in various applications:

- Smart Furniture: Adjusting beds, recliners, and other furniture for optimal comfort.

- Window Automation: Opening and closing windows and blinds remotely.

- Security Systems: Automating gates and doors for enhanced security and convenience.

Linear Actuators in Robotics

In the field of robotics, linear actuators are essential for providing precise movement and control:

- Robotic Arms: Facilitating intricate movements and tasks in assembly lines or laboratories.

- Automated Systems: Enhancing the efficiency and accuracy of robotic processes.

- Medical Robots: Assisting in surgeries and other medical procedures with precision and reliability.

Linear Actuators in the Automotive Industry

The automotive industry relies heavily on linear actuators for improving vehicle functionality and driver comfort:

- Adjustable Seats: Providing customizable seating positions for enhanced comfort.

- Window Regulators: Enabling smooth and reliable window operations.

- Trunk Lifts: Automating the opening and closing of trunks for convenience.

Future of Linear Actuator Technology

The future of linear actuators looks promising, with advancements in technology paving the way for more efficient and versatile applications:

- Smart Technology Integration: Incorporating IoT and AI for enhanced control and automation.

- Energy Efficiency: Developing actuators that consume less power and offer greater performance.

- Customization: Creating actuators tailored to specific industry needs and applications.

Maintenance and Care of Linear Actuators

Proper maintenance is crucial for the longevity and performance of linear actuators. Consider the following tips:

- Regular Cleaning: Keep actuators free from dust and debris to prevent wear and tear.

- Lubrication: Ensure moving parts are well-lubricated to reduce friction and increase efficiency.

- Inspection: Regularly check for signs of damage or wear, and address issues promptly.

Common Problems and Solutions

While linear actuators are generally reliable, they can encounter issues. Here are some common problems and their solutions:

- Overheating: Ensure proper ventilation and avoid overloading the actuator.

- Jamming: Check for obstructions and ensure the actuator is correctly aligned.

- Noise: Lubricate moving parts and inspect for wear or damage.

Frequently Asked Questions

- What is the lifespan of a linear actuator? With proper maintenance, most linear actuators can last several years, depending on usage and environmental conditions.

- Can linear actuators be used outdoors? Yes, there are weather-resistant models designed for outdoor use, capable of withstanding harsh conditions.

- How do I select the right linear actuator for my application? Consider factors such as load capacity, speed, and environmental conditions to ensure the actuator meets your needs.

- Are linear actuators energy-efficient? Yes, they typically require less power than other motion mechanisms, making them an efficient choice for many applications.

- Can linear actuators be controlled remotely? Yes, many actuators can be integrated with remote control systems for added convenience and automation.

- What maintenance is required for linear actuators? Regular cleaning, lubrication, and inspection are essential to ensure optimal performance and longevity.

Conclusion

Linear actuators are indispensable components in modern technology, offering precision, efficiency, and adaptability across various industries. From industrial machinery to home automation, their applications are vast and varied. As technology continues to advance, the potential for linear actuators to enhance and innovate our world is boundless. By understanding their types, applications, and maintenance requirements, users can harness the full potential of linear actuators, driving progress and efficiency in their respective fields.